QFlex® - Excellent quality and precision of flexographic printing on the print substrate

- 11 printing stations

- Cold Stamping

- printing on a metallized print substrate

- glossy or matte varnish using QProtect® technology

- full visual control of print quality

- 360-degree print

QFlex® New materials, new possibilities

- metallized – 100% of the surface

- transparent or white

- tubes with diameters of 35, 40 and 50 mm

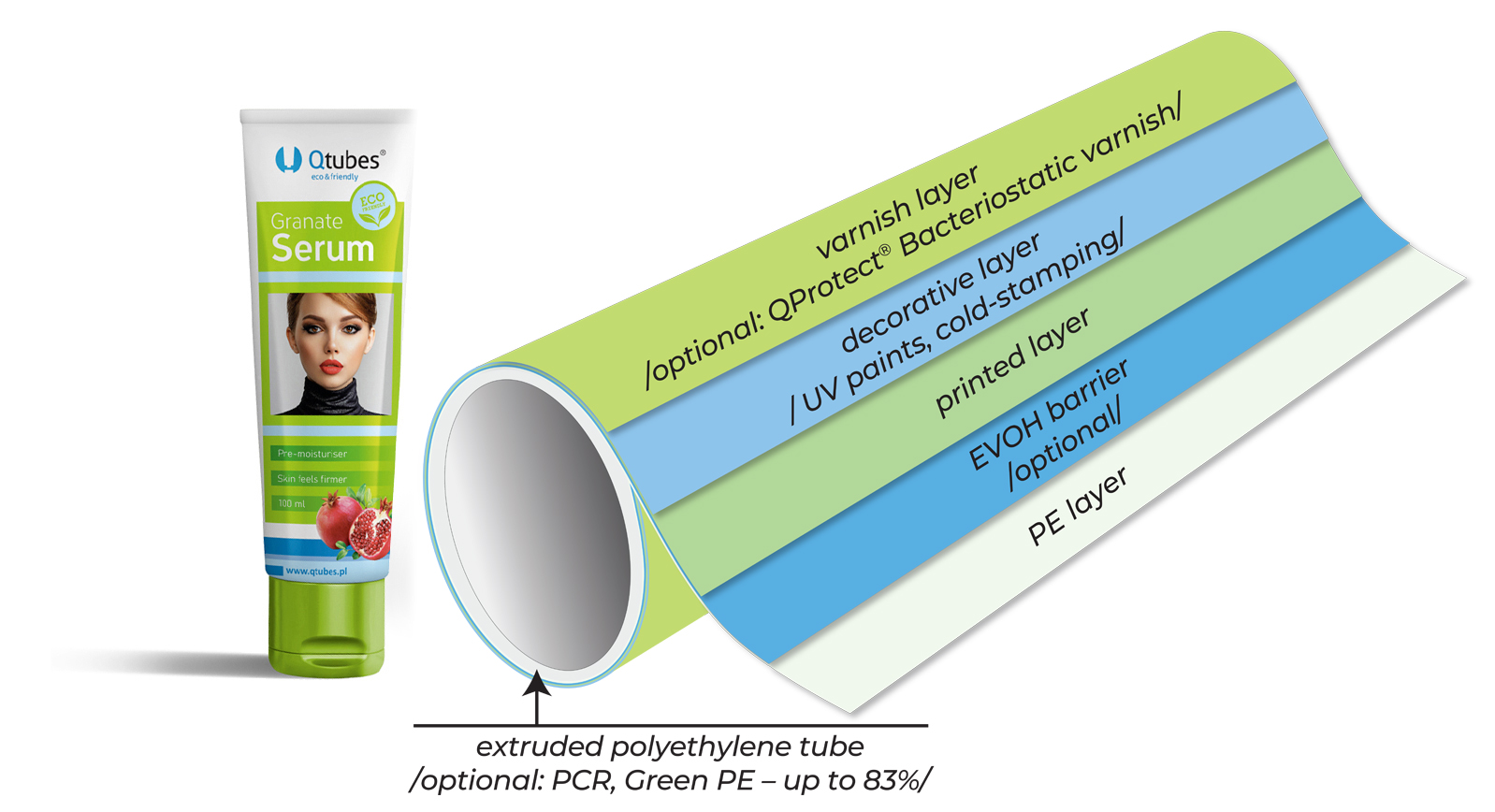

QFlex® Tube structure

- extruded PE tube (option: PCR, green PE)

- PE layer

- EVOH barrier (optional)

- printing layer (optional: PET, PP, PE or 100% metallized)

- decorative layer (UV paints, cold stamping)

- varnish layer (optional: QProtect® bacteriostatic varnish)

QFlex® Care for the environment

- production of cosmetic tubes according to the 3R philosophy – REDUCE, REUSE, RECYCLE

- the possibility of producing a tube consisting of PCR or BIO materials up to 83% of its volume

- minimal amount of waste

QFlex® EVOH barrier

- an excellent barrier against oxygen, nitrogen, carbon dioxide and helium

- reduces the need for preservatives and extends the possible shelf life of the product

- the smell, color and freshness of the products remain intact

- recyclable and environmentally safe

Screen printing

- special colors

- selective and effect varnishes

- additional decorations

Our technology allows us to obtain a tube fully or partially metallized and covered with glossy or matte QProtect® varnish.

Read more

Along with the changing reality, we offer tubes with the QProtect® coating that stops the growth of unwanted bacteria and prevents bacterial infections.

Read more

The requirement of the modern world is daily adaptation to the conditions of the changing reality following the changing needs.

Read more